EKD Adjustable Shock Absorbers can simply adjust to fulfill different input speed and force. This series product canadapt to various applications and working conditions. By simply turning an adjustable knob, the damping force canbe changed to accommodate a wide range of conditions. Adjustable shock absorbers can be used for absorbingharmful impact on precision components that is driven by cylinder, motor or mass load, etc.

EKD standard adjustable EK Series provides an adjustable knob offered in metric thread configurations with strokelengths of 25-150mm. EKD low range adjustable EKL Series products are available to control velocities as low as0.08m/s and propelling forces as high as 17790N, with excellent batch stability.

Features and Benefits:

● Adjustable design lets you “fine-tune” yourdesired damping and lock the numberedadjustment setting.

● Internal orifice design provides excellentdeceleration performance and energy absorptionefficiency with efficient damping characteristics.

● EKD product is well known for its excellentperformance in reaction forces in the industry.

● Threaded cylinders provide mounting flexibility andincrease surface area for improved heat dissipation.

● Incorporating optional fluids and seal packages canexpand the standard operating temperature rangefrom (-10°C - 80°C) to (-40°C - 100°C).

● ISO quality standards ensure reliable, long-lifeoperation.

● Adjustable design makes EKD products suitable for awider range of application, from low range products tohigh performance products.

● A select variety of surface finishes with nickel platingprocessing provides longest corrosion resistanceprotection.

● New all stainless steel products are available, including304 series, 316 series and 316L series.

EKD Adjustable Multiple Orifice Shock Absorbers

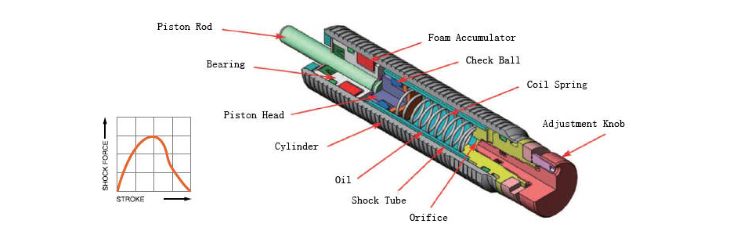

Conventional damping allows lineardeceleration by providing a constant shockforce over the entire stroke. This standarddesign is the most efficient, meaning it allowsthe most energy to be absorbed in a givenstroke, while providing the lowest shock force.This type of damping is also available inadjustable shock absorbers.

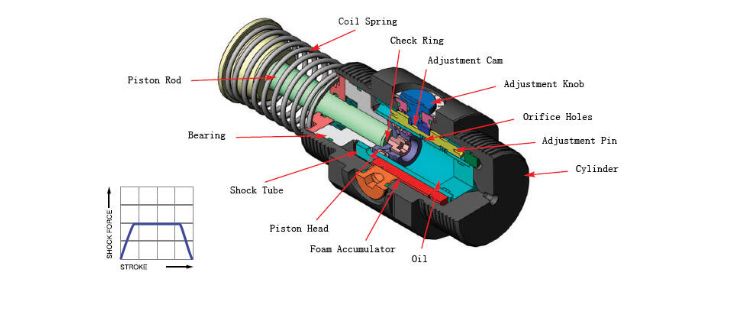

The adjustable multiple orifice shock absorberis similar to the principles described earlier.The check ring replaces the check ball and theadjustment feature uses an adjustment pininstead of an adjustment ball. The dampingforce of the shock absorber can be changed byturning the adjustment knob. Maximumdamping force is achieved by turning theadjustment knob to eight, while minimumdamping force is achieved by turning theadjustment knob to zero.

Turning the adjustment knob rotates the adjustment cam within theshock absorber. The cam, in turn, moves the adjustment pin in the shocktube, closing or opening the orifice holes. By closing the orifice holes, thetotal orifice area of the shock absorber is reduced, thus increasing thedamping force of the shock absorber. The adjustable shock absorberenables the user to change the damping force of the unit, should inputconditions change, while still maintaining a conventional-style dampingcurve. Low velocity range series configurations are available forcontrolling velocities that fall below the standard adjustable range.

EKD Adjustable Multiple Orifice Shock Absorbers

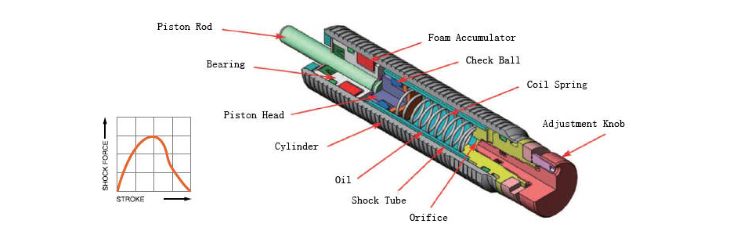

Conventional damping allows lineardeceleration by providing a constant shockforce over the entire stroke. This standarddesign is the most efficient, meaning it allowsthe most energy to be absorbed in a givenstroke, while providing the lowest shock force.This type of damping is also available inadjustable shock absorbers.

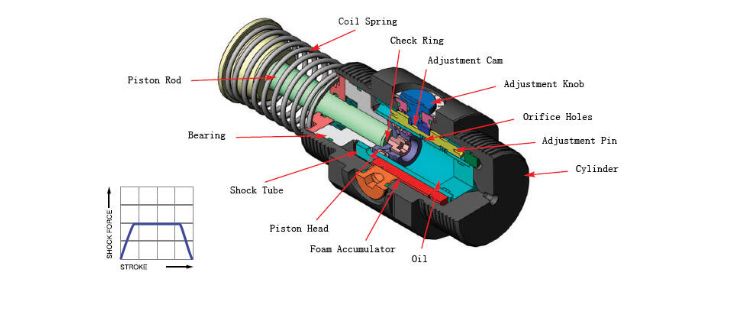

The adjustable multiple orifice shock absorberis similar to the principles described earlier.The check ring replaces the check ball and theadjustment feature uses an adjustment pininstead of an adjustment ball. The dampingforce of the shock absorber can be changed byturning the adjustment knob. Maximumdamping force is achieved by turning theadjustment knob to eight, while minimumdamping force is achieved by turning theadjustment knob to zero.

Turning the adjustment knob rotates the adjustment cam within theshock absorber. The cam, in turn, moves the adjustment pin in the shocktube, closing or opening the orifice holes. By closing the orifice holes, thetotal orifice area of the shock absorber is reduced, thus increasing thedamping force of the shock absorber. The adjustable shock absorberenables the user to change the damping force of the unit, should inputconditions change, while still maintaining a conventional-style dampingcurve. Low velocity range series configurations are available forcontrolling velocities that fall below the standard adjustable range.