Heavy Industry Shock Absorber was designed withGas-charged return system. This series product hasvery strong energy absorption capacity for singleshock, particularly suitable for safety stop of largeor super large equipments. Heavy Industry ShockAbsorbers are widely used in Cranes, Railequipments, Steel industry, Coal, Railway and otherfields. Large-Bore and High Energy Capacity designensures reliable energy absorption capacity andlong service life.

This type of products is particularly suitable forbuffer applications in safety protection. Singleproduct comes with the leading energy absorptioncapacity in the industry, stable performance duringlong stand-by time is also ensured.

Features and Benefits:

● Compact design, decelerates smoothly and safely,great energy absorption capacity loads up to 4 millionin-lbs(500KNm) per cycle with standard stroke lengths.

● Nitrogen-charged return system allows for softdeceleration and positive return in a maintenance-freepackage.

● Wide variety of optional configurations includingprotective bellows and safety cables.

● Available in custom-orificed non adjustable models.

● Special epoxy painting and rod materials are availablefor use in highly corrosive environments.

● Surface treatment(Sea water resistant)Housing: gray color, three-part epoxy Piston Rod: hard-chrome plated steel

● Optional galvanized surface finishes for newly upgradedproducts enhances corrosion resistance performance.

● Incorporating optional fluids and seal packagesavailable to expand standard operating temperaturerange from (-10°C to 60°C) to (-35°C to 100°C)

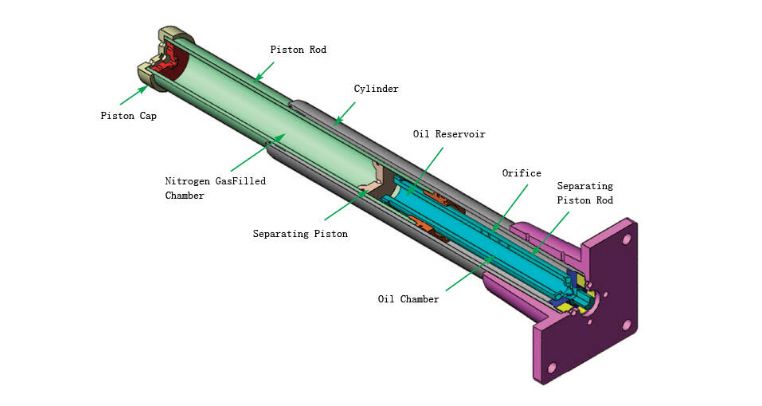

Characteristics of the EI Series products include a nitrogen-charged returnsystem that allows for soft deceleration and positive return in a maintenance-free package. The oversized bore area results in optimal energy absorptioncapabilities and increases internal safety factors. Strict assembly process controland product testing ensure the integrity of design and product performance.

Prior to EI Series shock absorber manufacture, computer-simulated responsecurves are generated to model actual conditions, verify product performance,confirm damping characteristics and generate unique custom-orificed designthat accommodates multi-condition or specific damping requirements.