EKD Non-Adjustable Hydraulic Shock Absorber wasdesigned of an integrated and non-detachable unit,powerful, compact and reliable, with high energyabsorption efficiency. This series product has very longworking life up to 25-30 million life cycles with excellentperformance stability. Non-adjustable shock absorber iswidely used for absorbing the impact and shock energyon high-frequency, precision equipments and providesperfect safety stop.

EN Series Non-adjustable Hydraulic Shock Absorbercomes with a self-compensating design, it canaccommodate high range and high frequencyconditions, while energy absorption performance in lowrange and high shock conditions is ensured. Surfacefinishes with nickel plating processing providesexcellent corrosion resistance protection.

New all stainless steel products are available, including304 series, 316 series and 316L series.

Features and Benefits:

● Extensive non-adjustable product line offers flexibilityin both size and energy absorption capacity to fulfill awide range of application requirements.

● Tamperproof design ensures repeatable performanceand super long service life.

● Special materials and finishes can be designed to meetspecific customer requirements.

● Incorporating optional fluids and seal packages canexpand the standard operating temperature rangefrom(-10°C-80°C) to (-40°C-100°C).

● Threaded cylinders provide mounting flexibility andincrease surface area for improved heat dissipation.

● A select variety of surface finishes maintains originalquality appearance and provides the longest corrosionresistance protection.

● ISO quality standards ensure reliable, long-lifeoperation and very high batch stability.

EKD Adjustable Single Orifice Shock Absorbers

Self-compensating damping

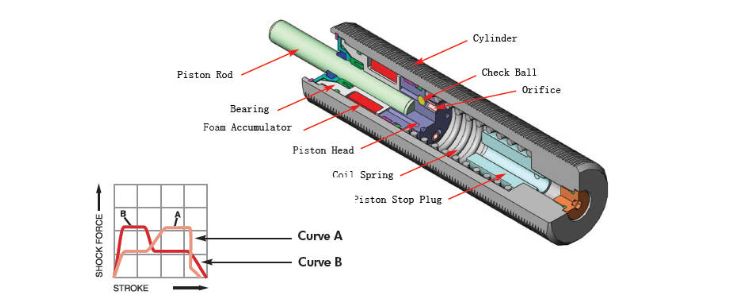

Self-compensating damping maintains acceptable deceleration with conventional type damping characteristics.Self-compensating shock absorbers operate over a wide range of weights and velocities. These shock absorbersare well suited for high drive force, low velocity applications, and where energy conditions may change. Curve Ashows the shock force vs stroke curve of a self-compensating shock absorber impacted with a low velocity andhigh drive force. Curve B shows the shock force vs stroke curve of a self-compensating shock absorber impactedwith a high velocity and low drive force.

The design of a multi-orifice shock absorber features adouble cylinder arrangement with space between theconcentric shock tube and cylinder, and a series oforifice holes drilled down the length of the shock tubewall.

During piston movement, the check ring is seated andoil is forced through the orifices in the shock tubewall, into the closed cellular foam accumulator andbehind the piston head.

As the piston head moves, it closes off orifice holes,thus reducing the available orifice area in proportionto the velocity. After the load is removed the coilspring pushes the piston rod outward. This unseatsthe check ring and permits the oil to flow from theaccumulator and across the piston head, back into theshock tube. This allows quick repositioning for thenext impact.

Low Pressure multiple orifice shock absorbers canprovide progressive or self-compensating damping,depending on the impact conditions.